The

TRACE-P mission deployment depends upon the coordinated efforts of many persons

and organizations. The following

sections provide details for each activity associated with the deployment sites,

the Team members and airplanes. Table

7.0-1 provides a one-page summary of these activity and indicates who is

involved in their implementation.

TRACE-P is a research project within the NASA Global Tropospheric Experiment (GTE) series, managed and funded through the Tropospheric Chemistry Program in the Earth Science Enterprise Office (ESEO). The Program Manager for the Tropospheric Chemistry Program serves as the TRACE-P Program Manager. TRACE-P Project activities are managed by the GTE Project Office at NASA's Langley Research Center (LaRC).

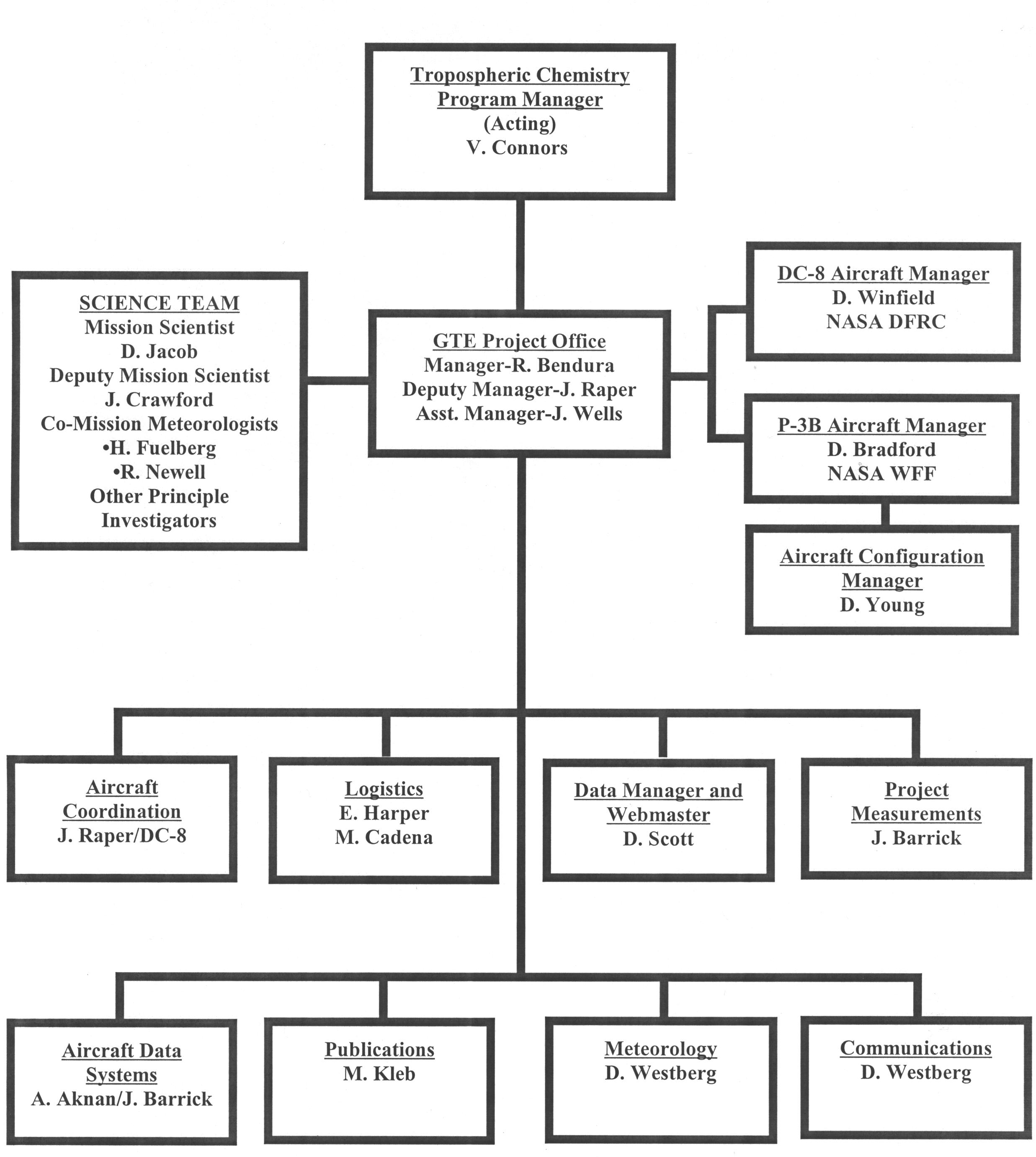

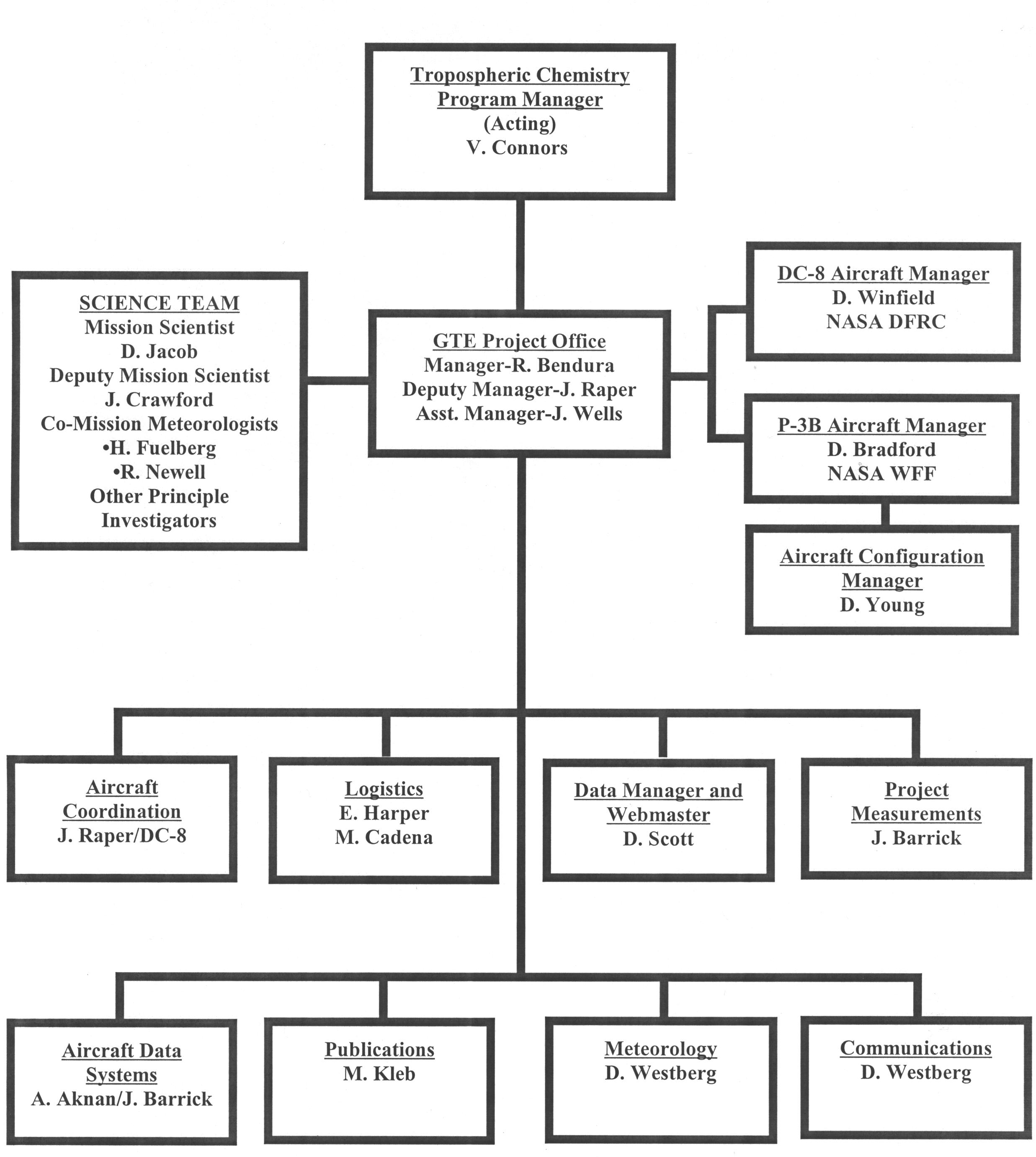

The functional organization for implementing GTE/TRACE-P is shown in Figure 7.1-1. Names, organization and telephone numbers of all project personnel are provided in Appendix H. A brief description of the TRACE-P team responsibilities for major functional elements follows:

Tropospheric Chemistry Program Manager: Provides oversight to ensure that the research activities of TRACE-P are in concert with the objectives of the ESEO. The Program Manager will be the point of contact for coordinating the research activities of TRACE-P with other collaborating U.S. and foreign agencies, if applicable. The Program Manager will be an ex-officio member of the TRACE-P Science Team.

GTE Project Office: The GTE Project Manager, with the assistance of the Deputy Project Manager, will be responsible for the overall management and coordination of resources provided to meet the scientific objectives of the TRACE-P mission. These responsibilities will include (a) interaction with the Tropospheric Chemistry Program management and the management of other collaborating agencies and science teams; (b) overall direction and documentation of project planning, schedules, and field operations; (c) providing for the timely transmittal of all data collected by the project into the LaRC DAAC; and (d) acquisition and reporting of base measurements in support of the mission goals. Also, in concert with the NASA Office of External Affairs and the U.S. Department of State, determine and assure compliance with host country requirements for foreign country operations. The Project Manager/Deputy Manager will be assisted by the Mission Scientist, Deputy Mission Scientist, Co-Mission Meteorologists, Assistant Project Manager and by the project staff. The Project Manager (or in his absence the Deputy Project Manager) will be an ex-officio member of the TRACE-P Science Team.

Mission Scientist/Deputy Mission Scientist: Responsible for guidance of all scientific aspects of the expedition, including being the chief scientific spokespersons for the Project, chairing Science Team meetings, and establishing with the Project Manager and PIs, the detailed flight objectives and requirements. The Mission Scientist will also be responsible for providing overall guidance to the TRACE-P Science Team and for directing publication of the mission results. The Mission Scientist and Deputy Mission Scientist are responsible, with the advice of the Science Team, for assisting the Aircraft Managers in the preparation of each mission flight plan.

Co-Mission Meteorologists: Responsible for the coordination of all meteorological functions, including forecasting and planning for all aircraft flights and all meteorological data products. Co-Mission Meteorologists are also responsible for determining and, with the aid of the Project Office, arranging for meteorological support at the deployment sites. They will also chair Science Team meetings in the absence of both the Mission Scientist and the Deputy Mission Scientist.

Principal Investigators: Responsible for the scientific instrumentation/modeling as well as data gathering, reduction, analyses, archival and publication. PIs will also contribute to the mission planning process to ensure the best operational use of their individual experiments/models for the overall science objectives of the TRACE-P mission. Instrument PIs are responsible for determining instrumentation support requirements at the integration and deployment sites and submitting them to the Aircraft Manager or Logistics Manager as appropriate.

Aircraft Managers: Responsible for installation of Project approved PI and Project instrumentation aboard their respective aircraft. Responsible for flight scheduling and for coordination of flight planning activities between Mission Scientist and aircraft flight crew. Responsible for in-flight communications between the science team and the aircraft crew. Responsible for aircraft payload layout, hazard analysis, engineering reviews, and inspections. Coordinates payload installation and check-out, and payload removal. Obtains safety and flight readiness approvals and aircraft diplomatic clearances. Responsible for direct aircraft logistical support, aircraft customs clearances, and transport of aircrew and aircraft science staff to and from airport and hotel upon initial arrival and final departure each non-intensive (e.g. overnight) site.

Aircraft Configuration Manager: Oversees the installation of all mechanical/electrical additions/deletions to the NASA P-3B airframe for net effect upon structural integrity, handling qualities, performance, and customer safety and comfort.

Aircraft Coordination: Project Office personnel responsible for assisting the Aircraft Manager(s) in the scheduling and coordination associated with the integration of experiments and/or the loading of cargo aboard the aircraft. Also work with the Mission Scientist and PIs to meet mission flight objectives. Is senior Project Office representative in the absence of the Project /Deputy Project Managers.

Site Managers: A GTE Project Office person will serve as the On-Site Manager at the sites from which the three airplanes operate. The Site Manager is a single point of contact for the whole TRACE-P Team for all field-related issues associated with support of mission implementation. The Site Manager will identify issues and coordinate their timely resolution with aircraft, operations, science, and facility representatives. The Site Manager reports to the Project Manager. Table 7.1-1 identifies the Site Managers

Logistics: SAIC personnel responsible for all (except direct aircraft) logistical support throughout the expedition, especially for arrangements for shipping, lodging, travel, personnel and equipment transportation at intensive sites, procurement of Project-furnished expendables, and travel expenses for non-NASA and non-foreign participants. Responsible for determining and implementing badging requirements at all sites.

Data Manager and Webmaster: Responsible for the receipt, assembling, archiving, and distribution of PI-submitted and Project data. Responsible for accuracy, currency, format, and content of GTE homepage.

Project Measurements: Investigator responsible for the integration, maintenance, and operation of instrumentation utilized for Project measurements; video display and recording; and real time data distribution to other principal investigators. Also responsible for analysis, reporting, and submission of Project data to the Data Manager for archival.

Aircraft Data Systems:

Personnel responsible for integration, maintenance, software development, and

operation of Project aircraft data acquisition systems.

Also responsible for real time and post-mission dissemination of Project

data to TRACE-P investigators

Publications: Responsible

for preparation of the TRACE-P Expedition Plan and JGR Mission Overview Paper.

Also assist in the preparation of other Project documentation such as Data

Compendium Report, DAAC Data Guide and Data Set Documents, Mission Aircraft

Navigational and Meteorological Data Report and Mission Chemical Data Plot

Reports

Meteorology: Responsible for assisting the Mission Meteorologists in the assembly, compilation, forecasting, generation, distribution and archival of meteorological information for real time and post-mission use.

Communications: Responsible for establishing Project and PI internet communications at operations sites as required and PI communications between mission aircraft.

|

Description/Location |

Wallops P-3B |

DFRC |

Kona |

Wake P-3B/C-130 |

Guam All |

Hong Kong All |

Okinawa P-3B/DC-8 & All |

Yokota |

Iwakuni |

Midway |

|

|

Engineering |

WFF |

DFRC |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

|

Fabrication |

WFF |

DFRC |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

|

Flight Hours |

WFF |

DFRC |

Each A/C |

WFF |

Each A/C |

Each A/C |

Each A/C |

Each A/C |

WFF |

WFF |

|

|

Aircraft Crew Travel Expenses |

WFF |

DFRC |

Each A/C |

WFF |

Each A/C |

Each A/C |

Each A/C |

Each A/C |

WFF |

WFF |

|

|

Overtime |

WFF |

DFRC |

Each A/C |

WFF |

Each A/C |

Each A/C |

Each A/C |

Each A/C |

WFF |

WFF |

|

|

P-3B Mission Mgr. |

WFF |

N/R |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

|

LN2 |

SAIC |

DFRC |

SAIC |

C-130 |

SAIC |

SAIC |

N/A HK 2&3; C-130 |

WFF pays; SAIC arranges |

P-3B |

N/A |

|

|

CO2 Ice |

SAIC |

DFRC |

SAIC |

N/A |

SAIC |

SAIC |

N/A HK 2&3; C-130 |

WFF pays; SAIC arranges |

P-3B |

N/A |

|

|

H2O Ice |

SAIC |

DFRC |

SAIC |

N/A |

SAIC |

SAIC |

N/A HK 2&3; C-130 |

WFF pays; SAIC arranges |

P-3B |

N/A |

|

|

C-130 |

WFF |

WFF |

WFF |

WFF |

WFF |

WFF |

N/A; WFF |

WFF |

N/A |

WFF |

|

|

Gases |

PI |

PI |

PI; C-130 & DC-8 |

PI; C-130 |

PI; C-130 |

PI |

DC-8; C-130 |

PI |

PI; P-3B |

PI |

|

|

Cars |

PI |

PI |

N/A-DC-8

only on return; PI pays |

N/A |

N/A |

N/R |

N/R |

WFF pays; SAIC arranges |

N/A |

N/A |

|

|

Hotel Lodging |

PI or contact SAIC for SAIC pay |

PI |

SAIC blocks, PI reserves and pays |

WFF blocks and reserves, PI pays |

SAIC blocks and reserves, PI pays |

SAIC blocks, PI reserves and pays |

DFRC arranges for all and pays over-nights, PI pays transit |

SAIC blocks and reserves, WFF pays |

WFF |

WFF blocks and reserves, PI pays |

|

|

Flight Lunches |

WFF |

DFRC |

Each A/C |

WFF |

SAIC plans, each A/C pays |

DFRC |

DFRC |

WFF |

WFF |

WFF |

|

|

Bus |

N/A |

N/A |

Westbound DFRC |

WFF |

SAIC |

DFRC |

DFRC |

N/A |

WFF |

WFF |

|

|

Taxis |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/R |

N/A |

N/A |

N/A |

|

|

Fuel Surcharge |

N/R |

N/R |

Each A/C |

WFF |

SAIC plans, each A/C pays |

DFRC |

DFRC |

WFF |

WFF |

WFF |

|

|

Landing Fees |

N/R |

N/R |

Each A/C |

WFF |

SAIC plans, each A/C pays |

DFRC |

DFRC |

WFF |

WFF |

WFF |

|

|

Parking Fees |

N/R |

N/R |

Each A/C |

WFF |

SAIC plans, each A/C pays |

DFRC |

DFRC |

WFF |

WFF |

WFF |

|

|

Badges |

Pers. ID |

Pers. ID |

SAIC |

N/R |

2 Pers. ID |

SAIC |

? |

2 Pers. ID |

? |

N/R |

|

|

Meeting Rooms |

WFF |

DFRC |

N/A; DFRC |

N/A |

N/A |

SAIC |

N/R |

SAIC arranges, WFF pays |

With ACE-Asia |

N/A |

|

|

Cell Phones |

N/A |

N/A |

N/A |

N/A |

N/A |

|

N/A |

SAIC arranges, WFF pays |

N/A |

N/A |

|

|

FBO |

N/R |

N/R |

Each A/C |

WFF |

SAIC plans, each A/C pays |

DFRC |

DFRC |

WFF |

WFF |

WFF |

|

|

Internet |

WFF |

DFRC |

N/A |

N/A |

N/A |

SAIC |

N/A |

SAIC |

N/A |

N/A |

|

|

Office Facilities & Equipment |

WFF |

DFRC |

N/A |

N/A |

N/A |

SAIC |

N/A |

SAIC arranges, WFF pays |

With A/A |

N/A |

|

|

Lab Space |

WFF |

DFRC |

N/A |

N/A |

N/A |

DFRC |

N/A |

SAIC arranges, WFF pays |

N/A |

N/A |

|

|

Non-A/C persons Travel Expenses |

Indivi-dual |

Individual |

Individual |

Individual |

Individual |

Individual |

Individual |

Individual |

Individual |

Individual |

Figure 7.1-1 TRACE-P Project Organization

|

Site |

Site

Manager |

Arrival Date |

Departure

Date |

||

|

Manager |

Plane |

Manager |

Plane |

||

|

Wallops |

John Wells |

1/2/01 |

- |

2/22/01 |

2/22/01 |

|

|

|

|

|

|

|

|

DFRC |

Jim Raper |

1/5/01 |

- |

2/26/01 |

2/26/01 |

|

|

|

|

|

|

|

|

Kona |

John Wells |

2/24/01 |

2/24/01 |

2/26/01 |

2/26/01 |

|

Kona |

Jim Raper |

2/26/01 |

2/26/01 |

2/27/01 |

2/27/01 |

|

|

|

|

|

|

|

|

Wake Isl. |

John Wells |

2/26/01 |

2/26/01 |

2/27/01 |

2/27/01 |

|

|

|

|

|

|

|

|

Guam |

Jim Raper |

2/28/01 |

2/28/01 |

3/2/01 |

3/2/01 |

|

|

|

|

|

|

|

|

Hong Kong |

Richard Bendura |

2/21/01 |

3/2/01 |

3/8/01 |

3/18/01 |

|

Hong Kong |

Erika Harper |

2/21/01 |

3/2/01 |

3/20/01 |

3/18/01 |

|

|

|

|

|

|

|

|

Okinawa |

Jim Raper |

3/9/01 |

3/9/01 |

3/10/01 |

3/10/01 |

|

Okinawa |

Jim Raper |

3/17/01 |

3/17/01 |

3/18/01 |

3/18/01 |

|

|

|

|

|

|

|

|

Yokota |

Richard Bendura |

3/9/01 |

3/18/01 |

4/6/01 |

4/4/01 |

|

|

|

|

|

|

|

|

Iwakuni |

John Wells |

3/26/01 |

3/26/01 |

3/27/01 |

3/27/01 |

|

|

|

|

|

|

|

|

Midway |

John Wells |

4/3/01 |

4/3/01 |

4/7/01 |

4/7/01 |

|

|

|

|

|

|

|

|

Kona |

Jim Raper |

4/3/01 |

4/3/01 |

4/8/01 |

4/8/01 |

|

|

|

|

|

|

|

|

DFRC |

Jim Raper |

4/8/01 |

4/8/01 |

4/11/01 |

- |

|

|

|

|

|

|

|

|

Wallops |

John Wells |

4/10/01 |

4/10/01 |

4/13/01 |

- |

Integration of instrumentation aboard the P-3B will occur

at the NASA Wallops Flight Facility and for the DC-8 at the NASA Dryden Flight

Research Center. The appropriate

Aircraft Manager is responsible for all phases of this activity.

This section will describe procedures and policies for each integration

site.

Prior to the arrival of experimenters and their equipment

at the integration sites, each experiment team must submit an Experimenter

Integration Questionnaire to their Aircraft Manager. This document will be used

to develop payload hazard analyses, electrical load schedules, mission peculiar

cost estimates, data distribution requirements, and laboratory requirements.

Inspections begin at the arrival of an experiment and

continue throughout the integration period. To assure success with inspections,

experimenters should consult frequently with aircraft inspectors regarding the

use of hardware, fasteners, and cable ties.

An Integration Engineer will be available to assist in the design and

fabrication of any required mounting brackets and clips, and to advise on

problems discovered during inspection. A

daily integration status meeting, chaired by the Aircraft Manager, will keep the

experimenter abreast of upcoming milestones and offer a forum for requests for

assistance. Timely action will be initiated to resolve problems that may delay

the installation schedule.

Storage bins in which small test equipment, tools, notes,

tapes, etc. may be stored are available for panel mounting on the PI racks.

The Aircraft Manager will arrange for these bins on request.

Operation of all equipment should be checked out in the

laboratory. Power connectors for

both 60 and 400-Hz, identical to those used in the aircraft, are available.

These connectors should be used to ensure that assembled equipment, in

each rack, would not trip the GFI devices in the aircraft.

7.2.2 Hangar Safety and Emergency

At DFRC and WFF experimenters work in an environment

generally unavailable to the public. The

laboratories are housed in hangers containing other aircraft, and it is

sometimes necessary to walk through the hanger and on to the ramp area.

The following precautions must be observed:

(1) No Smoking in the hanger, on the ramp, or aboard the

grounded aircraft.

(2) Look out for cables, hoses, boxes, tow bars, moving

vehicles, and movement of the hanger doors when crossing the hanger floor.

(3) Do not walk directly across the ramp.

Travel along the edges of the ramp when entering or exiting the DC-8 or

P-3B outside.

(4) Do not approach aircraft with engines running.

Jet exhaust or prop wash is dangerous for a considerable distance behind

the aircraft.

(5) Review posted evacuation procedures for hydrazine

emergencies (Dryden).

IN AN EMERG

dial this number from any phone.

Dryden- 911 Wallops- 1333

For Emergency Aid, Fire, Accident, Etc.

This emergency number is available at any hour.

Callers should also be able to describe their location (e.g. building and

room number) so that emergency help can respond promptly.

Before any equipment may leave the laboratory for

installation in the aircraft, an inspection is required for its compliance with

all safety requirements. The

inspectors are generally available throughout the checkout period, and they

should be asked for advice and assistance regarding the need for straps, trays,

or other special restraints during the process of assembly. They also look for other safety hazards, such as equipment

with sharp or projecting edges, and they will request that such hazards be

corrected (e.g. padding with a suitable material). The inspection will also

cover conformity to electrical safety requirements.

The inspector will check to see that all the cabling is properly secured

and protected against abrasion. A

check will be made to ensure proper equipment operation without tripping the

Ground Fault Interrupter (GFI) devices.

Each item of equipment placed aboard the aircraft must be

weighed and it's weight marked on it (removable tape may be used).

The total calculated weight and the overturning moment of each rack can

then be readily checked by an inspector. Scales are available in or adjacent to

the work area.

7.2.4 Install

Following inspection and approval, aircraft technicians

will transport and install the equipment aboard the aircraft.

They will be working to the cabin layout drawings and time schedule

provided by the Aircraft Manager. The

experimenters or their representative must be present during installation to

advise and assist as necessary. Following

the mechanical installation, the Electronic Technicians will work with the

experimenter. They will complete

the cabling installation from the aircraft systems to the experiment, and they

will advise as requested on cabling between racks and other experiment

equipment.

No work may be done in the aircraft unless a crewman or

other designated representative is present.

(Aircraft doors may not be opened or closed by any experiment personnel).

The aircraft is usually available on a two-shift basis, from 7:30 AM to

11:30 PM. Additional time,

including weekends, requires overtime for the ground crew and must be arranged

for in advance with the Aircraft Manager. Budgetary

limitations may preclude time in excess of two shifts on a five-day-week basis.

If special positioning of the aircraft is required for

experiment alignment or checkout, the Aircraft Manager should be notified a week

or more in advance. This will allow

time for obtaining the proper approval, and scheduling of ramp activities.

Laser tests may require NASA approvals, which often require several weeks

time.

Power is normally available on the aircraft for checkout

when the aircraft is in the hanger or parked on the ramp. At these times, power comes from the ground generators

producing 400-Hz ac. The stability of these sources is not necessarily as well

controlled as the aircraft engine generators used in flight. Power in 60-Hz form is obtained from the electronic

converters in the aircraft,

or from an external source of ground power.

Power distribution in the aircraft is controlled from the

Aircraft Manager's station. Experimenters

are not authorized to switch power at this location. Upon request, one of the aircraft Electronics Technicians,

the Aircraft Manager, his assistant, or a member of the ground crew will switch

power to the appropriate station.

Due to periodic maintenance and/or installation

procedures, the ground crew may need to shut down electrical power for short

periods of time. If power is needed

for an uninterrupted period of time for checkout of experimenter equipment

within the aircraft, the Aircraft Manager must be advised well in advance.

This will allow the work of the ground crew on the aircraft to be

coordinated with experimenter's needs.

The Aircraft Manager will designate a time for a power

check of all experiments. Each

experiment's power station will be turned on separately to make current

measurements at the Aircraft Manager's console.

This procedure is necessary to balance loads among the 60-Hz converters,

and to minimize interference among experiments from power transients.

If EMI is a concern, the experimenter should request

simultaneous operation of several experiments to determine if any problems

exist.

Following equipment installation, before any mission

flights, the aircraft will be weighed and the balance calculated to determine

the center of gravity. Thereafter,

weight and location of any equipment that is added or removed must be noted on

the record sheet for that purpose, posted near the front door of the aircraft.

This procedure is necessary to maintain the current weight and balance

record. Each experimenter is

responsible for his own equipment, and must post entries when items are removed

(even for short periods of time) or returned.

7.2.7 Aircraft Safety and Inspection

While working in the aircraft on the ground, all

participants must observe the following safety rules:

(2) No Electric Drills - or other tools with universal

electric motors may be used in the aircraft. Air-driven drills are available

during this period

(3) Only Small, Pencil-Type Soldering Irons - and

electronic-grade rosin-core solder may be used on the aircraft.

(4) No High Wattage Heat Guns - are permitted on the

aircraft. If it becomes necessary

to heat shrink insulation, the material must be taken off the airplane, where

such treatment can be performed safely.

(5) No Volatile Solvents - of any kind, are permitted

without prior approval of the Aircraft Manager.

The inspectors will recheck each experiment installation

on the aircraft for full conformity with all safety regulations.

Any deficiencies will be noted on an inspection sheet and attached to

each rack. These must be signed-off before the first flight.

Integration activity milestones for the P-3B and DC-8 are

included in Tables 7.2.8-1 and

7.2.8-2

Table 7.2.8-1 P-3B

Integration Schedule for TRACE-P

|

Date |

Event |

Responsibility |

|

Oct 5,

2000 |

All GTE

equipment currently at WFF located and secured in Rm W-146. |

Bradford |

|

Oct 24-26,

2000 |

Georgia

Institute of Tech. Lowboy Fit Check onboard WFF P-3. |

Young |

|

Oct 27,

2000 |

Aircraft

Transits and Data Flight Tracks prepared and sent to NASA Headquarters for

formation of the Diplomatic Clearance Message. |

Bradford |

|

Nov 1,

2000 |

Aircraft

back from overhaul |

|

|

Nov 1-24,

2000 |

P-3B

grounded at WFF for repairs of floorboard, control cables, 90 day

maintenance, transversal beam repair, and other misc. repairs |

Young and

? |

|

Nov 6,

2000 |

Flocke

probe at WFF to begin installation on DC-8 window plate. |

Flocke |

|

Early Nov |

2nd

Site Survey to Transit and Deployment Sites. |

Bradford |

|

Mid Nov |

PI’s to

ship probes, windows, fairings, and exhaust to WWF for early Dec

installation |

All PI’s |

|

Nov 27-Dec 1, 2000 |

Pilot

training and crew proficiency training – ONLY WORK WHICH ALLOWS A/C TO

BE FLIGHT READY MAY BE ACCOMPLISHED THIS WEEK |

Pali |

|

Nov 30, 2000 |

All

external probes at WFF for installation on aircraft during next 2 weeks |

PI’s/Bradford |

|

Dec 4-15,

2000 |

Do not

install any external appendages which prevent aircraft flight |

|

|

Dec 4,

2000 |

P-3 in

hanger for window plate assembly and fuselage installations 1.

Clark - fwd. starboard observation window ~FS 333 stbd side |

Piper

Piper/Barrick |

|

Dec 15, 2000 |

Preliminary

OSD for GTE TRACE-P completed |

Bradford |

|

Dec 18-29, 2000 |

Pilot

training and crew proficiency flights |

Pali |

|

Jan 2-5, 2001

|

Begin

Kondo Probe installation into DC-8 window plate. ~FS 740 stbd side |

Piper/Kondo Piper

|

|

Jan 9-12, 2001 |

Kondo side

mounted instrumentation installation phased in where possible |

|

|

Jan 9, 2001 |

Upload

Eisele/Cantrell instrument rack ~FS

333 port side |

Piper/PI’s |

|

Jan 10, 200 |

Upload Weber instrument rack

~FS 445 stbd side |

Piper/PI’s |

|

Jan 11, 2001 |

Upload Avery/Vay/Barrick instru. rack~FS

525 port side |

Piper/PI’s |

|

Jan 15, 2001 |

HOLIDAY |

|

|

Jan 16, 2001 |

Upload

Sachse/Shetter instrumentation rack

~FS 620 port side |

Piper/PI’s |

|

Jan 17, 2001 |

Upload Flocke

instrumentation rack

~FS 760 port side |

Piper/PI’s |

|

Jan 23, 2001 |

Upload

Blake instrumentation rack

~FS 860 stbd side |

Piper/PI’s |

|

Jan 24, 2001 |

Upload Bandy single seat |

Piper/PI’s |

|

Jan 26, 2001 |

“POWER”

to all racks completed and initial checkout of all experimenter stations

verified as working |

Piper |

|

Jan 29-Feb. 2, 2001 |

Complete

installation all gas bottle racks |

Piper |

|

Feb 5, 2001 |

ALL ARB

actions finalized and written approval to proceed completed.

All PI’s en route or at WWF to participate in tomorrow’s real

time instrumentation tests. |

Cording |

|

Feb 6, 2001 |

All

instrumentation

“POWER-UP”

in hanger for RFI and POWER budget checks. |

Bradford/Piper Pali/Bradford |

|

Feb 6, 2001 |

Final QA

and ARB walk through of P-3B |

McNally/ |

|

Feb 7, 2001 |

Mandatory

Aircraft Safety Briefing |

Pali |

|

Feb 8, 2001 |

P-3B

Engineering Check Flight – 2 hours, instru. checkout |

Young |

|

Feb 9, 2001 |

GTE

TRACE-P Test Flight # 1 (all systems test) - 3 hours of Flight Profile #1 |

Bradford/Crawford |

|

Feb 12, 2001 |

GTE

TRACE-P Test Flight # 2 – 4 hours of Flight Profile #2 |

Bradford/Crawford

Bradford/Wells |

|

Feb 15, 2001 |

GTE

TRACE-P Test Flight # 3 - 6

hours of Flight Profile # 3 |

Bradford/Crawford

Bradford/Wells |

|

Feb 16, 2001 |

All

equipment to be transported on the C-130 at N-159 hangar ready for loading |

PI’s |

|

Feb 19, 2001 |

HOLIDAY |

|

|

Feb 21, 2001 |

Load C-130

A/C with essential baggage |

Piper |

|

Feb 22, 2001 |

BEGIN GTE

TRACE-P – Transit/data Flight, WFF to Dryden – 7 hrs. |

Pali/Bradford |

Table 7.2.8-2

DC-8 Integration Schedule for TRACE-P

|

Date |

Event |

Responsibility |

|

Jul-Dec 2000 |

Engineering

design & fabrication of DC-8 experiment interfaces |

|

|

NLT Dec 22, 2000 |

Experiment

integration equipment arrives.

Probes, cabling, wiring runs, plumbing, windows, and farings. |

|

|

Jan

02, 2001 |

Complete Experiment Conformance Reviews |

|

| Jan 03, 2001 | Chief Engineer’s Review | |

| Jan 04, 2001 | DC-8 Crew Hazard Briefing | |

| Jan 02-05, 2001 | Begin Installation of TRACE-P experimenter wire runs and plumbing, probes, windows, and fairings | |

|

Jan 08–14, 2001 |

All

experiment investigation teams at DFRC.

Attend Hangar 1623 Safety briefing. Final rack build-up, inspection, and

weigh-in begins. |

|

|

Jan 15, 2001 |

HOLIDAY

(facility access on request only) |

|

|

Jan 16-25, 2001 |

Rack

installation. Racks must be inspected

and weighed prior to loading. Install a/c power and DADS connections.

Begin experiment system operability and power checks. |

|

| Jan 18, 2001 | ICATS CCB for operational approval | |

| Jan 22, 2001 | ICATS Ground Operations Go/No Go | |

|

Jan 25, 2001 |

Complete

rack upload. Continue power and ICATS

installations and experimenter systems checks. Begin inspections for

flightworthiness. Once an experimenter clears inspection he/she may leave

Dryden. A representative from

each experiment must return for the Power Check on 30 Jan. All personnel

must attend the Mandatory Experimenter Safety Briefing on 12 Feb. |

|

| Jan 29, 2001 | Tech Brief | |

|

Jan 30, 2001 |

Power-up

Check. A representative from each

experiment must be in attendance to power up his/her equipment. This is a

check of the power system balance, and a functional check for electrical

interference between experimenters. |

|

|

Jan 31, 2001 |

Roll-out.

The aircraft is towed out of the hangar. All racks must be secured prior

to roll-out. All windows, probes, and associated plumbing are installed

and inspected. Aircraft is pressure checked, defueled, and weighed. No

access to the aircraft until cleared by the Crew Chief. Weight management

begins on aircraft. All flight items brought aboard or removed, weighing >10

lbs., must be logged (wt. and sta.#). |

|

|

Feb 01, 2001 |

Engineering Check Flight in

AM. ICATS Test Flight in PM.

No experimenter access. |

|

| Feb 02, 2001 | Pilot Proficiency Test Flight | |

| Feb 09, 2001 | RVSM Certification Flight and ICATS Performance Checks | |

|

Feb 02-10, 2001 |

Ground

LASER Calibrations |

|

|

Feb 12, 2001 |

Mandatory

Experimenter Safety Briefing. |

|

|

Feb 14, 2001 |

Experimenter test flight

#1. |

|

| Feb 15, 2001 | Operational Readiness Review | |

|

Feb 16, 2001 |

Experimenter test flight

#2. |

|

|

Feb 19, 2001 |

HOLIDAY

(facility access on

request only) |

|

|

Feb 20, 2001 |

Experimenter test flight

#3. |

|

| Feb 21, 2001 | C-130 Cargo staged by noon. Reserved for backup test flight if required | |

| Feb 22, 2001 | C-130 and P-3B arrive from WFF | |

| Feb 23, 2001 | Load C-130 | |

| Feb 24, 2001 | C-130 and P-3B depart for Kona, HI | |

|

Feb 26, 2001 |

Start

Deployment. Transit flight to Kona,

HI |

|

|

Feb 27, 2001 |

Transit to Anderson AB,

Guam (Cross Dateline and

arrive 28 Feb) |

|

|

Mar 02, 2001 |

Transit to Hong Kong.

(Local flights include an out-and-back to Okinawa on 9-10 Mar) |

|

|

Mar 14, 2001 |

Transit to Yokota AB, Japan |

|

| Mar 17, 2001 | Transit to Okinawa | |

| Mar 18, 2001 | Transit to Yokota AB, Japan (local flights include out-and-back to Okinawa on 30-31 Mar) | |

|

Apr 04, 2001 |

Transit to Kona, HI (Cross Dateline and arrive 03 Apr) (one local flight on 05 Apr) |

|

|

Apr 09, 2001 |

Transit to DFRC. End Deployment |

|

|

Apr 10-13, 2001 |

Download payload. |

|

Figures 4.2-1 and 4.2-2 show experiment locations aboard

the DC-8 and P-3B.

7.2.10 Supplies and Expendables at Integration Sites

In general, the NASA GTE Project Office provides only commonly used expendables such as liquid nitrogen and dry ice. PIs will supply their own dewars and transfer tubes. Specialized gases and supplies unique to an experiment are the responsibility of the investigator teams. Appendix I lists liquid nitrogen and dry ice requirements by both PI group and site, including both Wallops and Dryden.

Personnel at Dryden or Wallops for integration activities

will have badges issued at the Badge and Pass Office listing the point of

contact (Mark Pestana, Dryden; Dick Bradford, Wallops) and other pertinent

information. The face of the badge may or may not include a reference to the

airplane. The badge is to be visible at all times while on the Center. This

badge will also be used to determine whether a person can be on the aircraft.

This badge should be with aircraft passengers throughout the mission.

7.3 Experiment On-board Hardware

Tables M.1-1 and M.2-2 summarize experiment hardware aboard the P-3B and DC-8, respectively. The weight given includes all weight associated with the experiment: rack, instrumentation, exhaust(s), inlet(s), gas bottles, passenger(s), seat(s), dewars, pumps, personal equipment, etc. The first number given in the "number of operators" column indicates the number of operators during a transit flight and the second number given indicates the number of operators during intensive flights. The "blue boxes" column indicates the number and size of box. The "external mounts" column indicates the number of inlets (through flow), number of probes (no flow), the number of nadir/zenith sensors, and the number of other appendages. In the "exhaust ports" column the number of exhausts with and without venturis is indicated along with the number of bulkhead (BH) fittings for exhausts. In the "type power" column, the voltage is indicated first and the frequency in hertz is indicated second, the number of phases is indicated third and the number of amps for that type circuit is indicated fourth. In the gases column, ‘B’ designates the number of bottles below the floor and ‘R’ designates the number of bottles adjacent or in a rack. Tables M.2-1 and M.2-2 summarize the gases aboard the P-3B and DC-8, respectively. Each gas is pure unless otherwise noted in the ‘Dilution’ column

The P-3B and DC-8 aircraft will have combined overnight

stopovers or operational stays at 8 different sites (see Table

7.4-1). Appendix L presents relevant information about each site.

Examples are: lodging

location and phone number; per diem allowances; electrical voltage and

frequency; international phone access numbers; US embassy or consulate locations

and phone numbers; and time zone information.

Table

7.4-1.TRACE-P Operations

Sites

|

SITE |

AIRCRAFT |

|

Wallops Flight Facility, Virginia |

P-3B, C-130 |

|

Dryden Flight Research Center, California |

DC-8, P-3B, C-130 |

|

Kona, Hawaii |

DC-8, P-3B, C-130 |

|

Wake Island |

P-3B, C-130 |

|

Guam |

DC-8, P-3B, C-130 |

|

Hong Kong |

DC-8, P-3B, C-130 |

|

Yokota Air Force Base, Japan |

DC-8, P-3B, C-130 |

|

Midway Island |

DC-8, P-3B, C-130 |

The NASA GTE Project Office is responsible for all PI logistical support at the following sites: Wallops Flight Facility, Dryden Flight Research Center, Hong Kong International Airport, and Yokota, Air Base, Japan. NASA Wallops and NASA Dryden are responsible for supporting the P-3B and DC-8, respectively.

The NASA GTE Project Office will

coordinate the PI shipping operation through Science Applications International

Corporation (SAIC). PI's may use

the Project's shipping contractor to ship their equipment to and from the

aircraft integration sites, and to and from the intensive sites.

Shipments to all sites will be via surface transportation whenever

possible. For TRACE-P a cargo

aircraft will transport the DC-8 and P-3B's aircraft support equipment, blue

boxes, and PI luggage along the TRACE-P flight path.

At each intensive or overnight site, the Project Office will coordinate for lodging accommodations, meeting rooms, certain cryogenics, and field laboratory facilities for every deploying mission participant.

The NASA GTE Project Office,

through SAIC, will financially support all non-NASA TRACE-P investigators'

allowable travel expenses associated with the planning of and participating in

TRACE-P. Travel costs for

government employees or non-US PI group foreign nationals will be covered by

their organizations. The NASA GTE

Project Office pays for all TRACE-P shipping operations coordinated by SAIC.

Both the DC-8 and P-3B have very limited space for

storing support equipment and supplies on board.

Therefore, the SAIC GTE Project Office will arrange for shipments to

pre-stage the support equipment and supplies for all investigators.

Shipping Agent: The SAIC GTE Project Office has contracted with AFC Worldwide Express to coordinate and expedite both foreign and domestic shipping. AFC will arrange for pick-up of equipment and supplies at the PI location for delivery to DFRC and/or WFF and to the intensive sites. AFC's overseas agents will expedite shipments through customs and handle return shipment operations.

Advance Shipping (Ocean):

Advance boat shipments will be made to Hong Kong and Yokota Air Base, Japan. All equipment and supplies needed at the intensive sites but

not needed for experiment integration at DFRC or WFF should be included in these

shipments.

Cargo Shipping: The WFF C-130 has been dedicated to TRACE-P to transport blue

boxes, aircraft support equipment, and other mission equipment which can neither

be pre-shipped nor carried on the mission aircraft.

The C-130 will follow the P-3B during the mission.

Shipping Between Intensive

Field Sites: Individuals flying on commercial airlines may transport

equipment as personal luggage subject to normal constraints and charges.

To avoid excess size and weight charges, items should be boxed such that

sum of the length, width, height does not exceed 62 inches, and total weight is

70 lbs. or less.

Shipping Responsibilities: The SAIC GTE Project Office is responsible for overseeing the shipping contract with AFC Worldwide Express. AFC is responsible for all shipping procedures and coordination.

PI's will:

·

maintain shipping weights within proposal estimates;

·

contact AFC Worldwide Express for coordination of pick-ups;

·

crate and label shipping items, following AFC's instructions;

·

provide a complete list of each container's contents, following

AFC's instructions;

·

label and document Hazardous Materials per national and

international shipping regulations for overland, air, and sea shipments as

applicable;

·

ship emergency items from the US after DC-8 or P-3B deployment;

·

ship samples from foreign sites to analysis labs (Project Office

can assist);

· provide any required licenses or permits for shipping specialized equipment (if you have such equipment, contact AFC for further information);

·

prepare return shipments from each intensive and offload site,

again following AFC's instructions.

Payment

for Shipping: A GTE account will be established with AFC Worldwide Express

for all shipping. PIs may charge

all items listed in their proposals or approved by the SAIC Project Office to

this account.

S

Shipping

Guidelines

All possible equipment and expendables must be pre-shipped to the deployment sites. The only items that will be considered for transport aboard the C-130 are those that are either needed at the integration sites but which must also be carried on deployment, or are needed at the transit sites. The Project Office will supply PI-identified amounts of LN2 and wet and dry ice at all sites. Local suppliers will be used at the integration and deployment sites. PI-identified amounts of these expendables will be transported aboard the C-130 to the transit sites. Each PI must supply his other expendables such as gases, chemicals, water, etc. These items will be either pre-shipped to the deployment sites or carried aboard the C-130 for use at transit sites. Items to be carried aboard the C-130 can be shipped to either Wallops, for P-3B instruments, or Dryden for DC-8 instruments. PI’s having items on the C-130 are expected to assist in loading and unloading. PI’s should contact Roy Chesson, SAIC GTE Project Office, to coordinate the shipment of items aboard the C-130

The SAIC GTE Project Office will review the questionnaires that have been returned by the PI groups and will distribute to each PI group a summary of their C-130 cargo requirements. Each PI group will need to review the summary and either confirm the information or provide changes. PI’s should coordinate TRACE-P pre-shipments directly with the mission-contracted freight forwarder as detailed in the next section.IN SUMMARY

Aircraft Loads:

P3-B: carries only instruments, operators and crew.DC-8: carries only instruments, operators, crew, overnight bags, and luggage. Luggage will not be accessible at all transit sites; overnight bags will be accessible.

C-130: carries P-3B overnight bags and luggage; blue boxes for both aircraft; expendables, gases, etc. for both aircraft; aircraft equipment for both aircraft. At every site, the C-130 will be accessible for P-3B overnight bags, site designated expendables, and critical blue boxes. P-3B luggage will not be accessible at transit sites.

Pre-shipments:

To Wallops: items needed to support P-3B integration and items to go on C-130 as cargo including expendables needed for all transit flights to Hong Kong.

To Dryden: items needed to support DC-8 integration; items to go on C-130 as cargo, including expendables needed for all transit flights to Hong Kong; items for P-3B during both transit stops.Kona, Wake Island, Guam, Okinawa, Iwakuni and Midway Island: no pre-shipments.

Hong Kong: All equipment needed that was not required for integration or at transit sites. This includes all gases that will be needed in Hong Kong.Yokota Air Base: All equipment needed that was not required for integration or at transit sites. This includes all gases that will be needed at Yokota and gases needed for return transit to US.

Source of Expendables: At Wallops and Dryden: the Project Office will purchase PI-designated amounts of LN2 and wet and dry ice from local suppliers. Gases and other expendables will come from PI pre-shipments. At Kona, Wake Island, Guam and Midway Island: gases, etc. needed for change-out on DC-8 and P-3B will come from the C-130. At Kona and Guam: the Project Office will purchase PI-designated amounts of LN2 and wet and dry ice from local suppliers. At Wake Island and Midway where there are no local LN2 or ice suppliers: the C-130 will carry PI-designated amounts of LN2 and wet and dry ice for replenishment of both the DC-8 and P-3B instruments.For the overnight flights (DC-8 to Okinawa and P-3B to Okinawa and Iwakuni): Pi’s will need to carry on the DC-8/P-3B any expendables they will need for the return flight. This includes LN2 and dry ice.

7.5.2 Travel

Support Coordination

SAIC-Supported Participants: The NASA GTE Project Office, through SAIC, will fund TRACE-P PI allowable travel expenses for all approved non-NASA participants in accordance with NASA and SAIC travel regulations. SAIC-supported personnel will make their own commercial flight reservations by contacting SAIC Travel. Please e-mail preferred itineraries to BOTH Leanne Hester (carole.l.hester@saic.com) AND Tanja Grande (tanja.grande@saic.com). Due to the volume of requests received, e-mail is the preferred method of contacting SAIC Travel. If you must phone SAIC Travel (l-800-435-1491 or 757-826-3248), please call during normal working hours (Eastern time) and speak with Leanne Hester or Tanja Grande. For full complete travel and reimbursement procedures and instructions, SAIC-supported travelers should refer to Erika Harper's e-mail dated December 5. This information is also available on the SAIC Project Support Office's website, http://lposun.larc.nasa.gov/pso/ (GTE>SAIC TRACE-P Logistics>Information for Supported Travelers).

NASA and Other Government Participants: These personnel are expected to make travel arrangements according to the procedures of their organizations.

Rental Cars: Rental cars are authorized at NASA Wallops Flight Facility, NASA Dryden Flight Research Center, Yokota Air Base, and Kona (DC-8 travelers on the return portion [April 3 - 8] only), under the guideline of one vehicle per PI aircraft team. Each team is responsible for making its own rental car arrangements at Wallops and Dryden. SAIC-supported participants should coordinate their reservations through the SAIC Travel Office. SAIC will make the arrangements for the PI groups in Yokota. Except for Yokota, where the Project will pay directly for rental cars, all participants will pay for their own rental cars. Payments will be reimbursed after travel vouchers have been submitted. NOTE: per government travel regulations, NASA personnel are not authorized to travel in contractor-rented vehicles (contractors include non-NASA PIs). However, contractors can be passengers in vehicles rented by NASA personnel. Taxis or project-arranged transportation (shuttle bus, etc.) will be at all other locations.

Special note concerning Hong Kong transportation: Because the Project's contracted lodging facility is co-located with the airport from which TRACE-P will be working, and because there are numerous restaurants in both the hotel and the adjoining airport, it is the Project's policy that train, taxi and other "mass transit" expenses will be considered a personal expense. Only such expenses incurred for business purposes are considered a business expense. The Project will arrange and directly pay for transportation (shuttle bus) between the hotel/airport, the TRACE-P laboratory facilities, and the NASA airplanes.

7.5.3

Passports, Visas and Access Badges

Passports: All TRACE-P participants must have a valid passport with an expiration date at least six months past the date of the end of the mission.

Visas: Visa requirements can be found in Appendix J -- Passports and Visas.

Anyone requiring a visa should check with the embassy or consulate of the country being visited regarding specific requirements for obtaining a visa. Neither NASA nor the SAIC GTE Project Office personnel can obtain visas for travelers. The Project Office can provide letters describing the mission and substantiating the applicant’s participation. The Project Office can also support any required travel to an embassy or consulate. NASA and other U.S. Government employees using official passports should check with their own organizational sources for obtaining visas.

Access Badges: Personnel information sheets are required from all TRACE-P participants for all TRACE-P operational sites (NASA Wallops Flight Facility; NASA Dryden Flight Research Center; Kona, HI; Wake Island; Guam; Hong Kong; Yokota Air Base; and Midway Island).

Specific badge requirements for each location are:

NASA Wallops Flight Facility: badge required; coordinated by D. Bradford at

NASA WFF

NASA Dryden Flight Research Center: badge required; coordinated by D. Winfield at NASA DFRC

Kona, HI: badge required; coordinated by SAIC GTE Project Office; those traveling to Kona must submit 2 passport-size photos to SAIC

Wake Island: badge not required

Guam: badge not required; participants must carry two (2) forms of identification with them at all times

Hong Kong: badge required; coordinated by SAIC GTE Project Office (those traveling to Hong Kong and who require aircraft or laboratory area access must return completed badge form to SAIC): photo will be taken upon arrival in Hong Kong

Yokota Air Base: badge not required; participants must carry two (2) forms of identification with them at all times

Midway Island: badge not required

PI's will identify all group members who require badges for DC-8 or P-3B aircraft access in the airport operational areas. The SAIC GTE Project Office will coordinate with the appropriate airport security offices for badge information requirements and submission dates.

All TRACE-P participants should submit two (2) passport-sized photos to the SAIC GTE Project Office. These photos are exclusive of any required for visas. Please write on the back of each photo the name of the person in the photo and mail to:

SAIC

GTE Project Office

One Enterprise Parkway

Suite 300

Hampton, VA 23666-5845

757-827-4858 (phone)

These photos are a reimbursable expense for both SAIC-supported participants and NASA employees.

In lieu of a

badge, Yokota Air Base requires that all participants carry two (2) forms

of picture identification with them at all times (e.g. passport and US driver's

license).

7.5.4

Worldwide Caution Statement

The

following statement was issued as a public announcement by the U. S. Department

of State on January 5, 2001.

The

Department of State remains concerned about the possibility for terrorist

actions against United States citizens and interests throughout the world.

American citizens are reminded of the need to remain vigilant with regard to

their personal security. This Public Announcement is not in response to any one

particular threat or event but to emphasize the U.S. Government's ongoing

concern for the security of Americans overseas.

The Department of State continues to receive reports that prompt concern about the safety and security of both official U.S. Government personnel and private American citizens worldwide. As always, we take this information seriously. As a result, U.S. Government facilities worldwide remain at a heightened state of alert. In addition, U.S. Government facilities have and will continue to temporarily close or suspend public services as necessary to review their security posture and ensure its adequacy.

In

light of the above, U.S. citizens are urged to maintain a high level of

vigilance and to take appropriate steps to increase their security awareness to

reduce their vulnerability. Americans should maintain a low profile, vary routes

and times for all required travel, and treat mail and packages from unfamiliar

sources with suspicion. In addition, American citizens are also urged to avoid

contact with any suspicious, unfamiliar objects, and to report their presence to

local authorities. Vehicles should not be left unattended, if at all possible,

and should be kept locked at all times. U.S. Government personnel overseas have

been advised to take the same precautions.

U.S.

citizens planning to travel abroad should consult the Department of State's

Public Announcements, Travel Warnings, Consular Information Sheets at http://travel.state.gov/travel/cis_pa_tw/tw/tw_1764.html,

and regional travel brochures at http://travel.state.gov/travel/tips/brochures/brochures_1231.html,

all of which are available at the Consular Affairs Internet web site at http://travel.state.gov.

We will continue to provide updated information should it become available.

American citizens overseas may contact the American Citizens Services unit of

the nearest U.S. Embassy or Consulate by telephone or fax for up-to-date

information on security conditions. In addition, American citizens in need of

emergency assistance should telephone the nearest U.S. Embassy or Consulate

before visiting the Embassy or Consulate.

7.5.5 Emergency Contact Information

In

the case of an emergency, messages may be provided to personnel in the field by

contacting Don Scott at NASA Langley GTE Project Office.

Please limit such messages to emergencies.

Assistance in establishing contact will be appreciated.

Don may be contacted as follows:

Work phone: 757-864-4430

Work fax: 757-864-5841

e-mail: a.d.scott@larc.nasa.gov

Home phone:757-874-3121

Home Fax: 757-874-3368

Home e-mail: telatax@juno.com

7.5.6 Personal Baggage on DC-8 and P-3B

Personal baggage is generally of two types: suitcase containing all personal items for the deployment duration and an overnight bag containing personal items sufficient for a few days without access to a larger suitcase. P-3B personnel suitcases and overnight bags will be carried on the C-130. DC-8 personnel suitcases and overnight bags will be carried on the DC-8. Weight estimates are based on 50 lbs. for a suitcase and 20 lbs. for an overnight bag.

DC-8 personnel suitcases will be stored in the DC-8 cargo and will not be accessible in flight. DC-8 personnel overnight bags will be stored in the DC-8 cabin and will be loaded and unloaded at every stop by the owner.

P-3B and DC-8 personnel suitcases will be removed from the planes at the deployment sites, but will not generally be removed at the transit stops. The P-3B suitcases will be accessible at Hilo (eastbound and westbound). P-3B overnight bags will be accessible at all deployment and transit stops. The DC-8 suitcases will be accessible at Guam (westbound)

Carry-on items can be stored in the DC-8 overhead bins.

The P-3B has no usable overhead storage bins.

The SAIC GTE Project Office is unaware of any restrictions or requirements concerning the temporary importation of computers and ancillary devices into any TRACE-P site. Generally, any U.S.-bought computer and ancillary device can be temporarily exported to support this mission as long as the same is returned upon completion.

Note:

Specific information concerning reimbursement of lodging and other

expenses was disseminated to SAIC-supported travelers.

Questions concerning those procedures should be addressed to the SAIC GTE

Project Office at 757-827-4858.

NASA

Wallops Flight Facility Area:

All PI’s and mission participants are responsible for all aspects of

their own lodging arrangements in WFF area during the integration and

downloading phases of the mission, unless

they have made arrangements with the SAIC Project Support Office (see below).

PI’s and participants will deal directly with the hotel or a rental

property agency for all required arrangements.

Any PI groups receiving SAIC support that are planning to share

lodging arrangements (i.e., 2 or more group members living in a house or in an

extended living hotel), please contact the SAIC GTE Project Office prior to

making any arrangements. Participants

are responsible for paying their own hotel bills. Participants will be

responsible for any extra expenses incurred due to failure to notify the hotel

of changes. See Appendix

L (Lodging, Ground Transportation, and Per Diem Rates) for a list of hotels

in the WFF area, as well as per diem information.

Note:

Some SAIC-supported travelers may have made arrangements with the Project

Office for lodging directly paid by GTE. Those

individuals should follow the instructions provided directly to them by the SAIC

GTE Project Office.

Lodging DFRC Area: All PI’s and mission participants are responsible for all aspects of lodging arrangements in the DFRC area during the integration and downloading phases of the mission. PI’s and participants will deal directly with the hotel or a rental property agency for all required arrangements. However, for those arriving at NASA DFRC on the P-3 or C-130 aircraft in either February or April, Dick Bradford, P-3 Mission Manager, has made a block reservation for the group at the Inn of Lancaster. Participants need not put the reservation in their own name; rooms are being held in Dick Bradford's name and will be changed upon check-in. Any PI groups receiving SAIC support that are planning to share lodging arrangements (i.e., 2 or more group members living in a house or in an extended living hotel), please contact the SAIC GTE Project Office prior to making any arrangements. Participants are responsible for paying their own hotel bills. Participants will be responsible for any extra expenses incurred due to failure to notify the hotel of changes. See Appendix L (Lodging, Ground Transportation and Per Diem Rates) for a list of hotels in the DFRC area, as well as per diem information.

Lodging at Intensive Field Sites: The SAIC GTE Project Office has pre-selected hotels in Hong Kong, and Yokota based on operational considerations, cost, and availability. All participants are expected to stay at the selected hotels. Please see Appendix L for hotel names, and addresses, as well as specific information concerning reservations, payment, and per diem rates.

Lodging at Transit Sites: .Please see Appendix L for hotel names, and addresses, as well as specific information concerning reservations, payment, and per diem rates.

Ř Lodging Per Diem at Integration/Offload Sites and Intensive Field Sites: NASA travel regulations treat per diem for foreign travel the same as domestic travel: When applicable, lodging reimbursement will equal actual expenses up to a maximum amount, and a fixed daily meal allowance will be given.

*Allowable

per diem rates are the same for NASA and SAIC-supported participants.

Throughout the Expedition Plan, discussions concerning per diem rates

apply to SAIC-supported (i.e. non-US government) participants, but the

information should be similar for US government personnel.

Some variations may exist for some aspects among various government

organizations; those not supported by NASA or SAIC should check with their own

organizations for specific regulations.

The Centers for Disease Control and

Prevention (CDC) (http://www.cdc.gov./travel/index.htm)

and NASA (http://ohp.nasa.gov/alerts/)

provide guidance for travelers on the web which the GTE Project Office urges all

participants to access. Generally,

one should practice the same health precautions in Hong Kong and Japan as are

appropriate to the US. Persons with

potentially serious medical problems are requested to contact the GTE Expedition

Manager to work out contingency plans for medical attention, if the need should

arise.

Each participant should be aware that NASA and the GTE Project Office does not provide any health or life insurance for personnel involved in the TRACE P Expedition, although life insurance is available upon application to federal employees. Each individual should determine if and how their present coverage is effected if flying aboard a government aircraft such as the NASA DC-8 or the NASA P-3B. Note also that federal employees are covered 24 hours per day, while in travel status, by the Federal Employees Compensation Act. This act provides compensation for disability due to personal injury sustained while in the performance of duty or to an employment-related disease. Most states provide similar coverage to non-federal employees. When required, one must secure medical attention as appropriate, retain receipts and file a claim after return from the mission.

Please refer to Appendix N for additional details.

7.5.9 Supplies and Expendables

Integration and Intensive Sites

7.5.10 Field Communications Systems

The GTE Project Office will be responsible for insuring

that the necessary communication systems are available for conducting the

TRACE-P mission. In general, this

will include, dedicated telephone and fax service at the TRACE-P Operations

Centers at each intensive site. Additionally,

a satellite communication system will be used as the prime communication link

for access of meteorological parameters for flight planning.

Telephone and fax service will also be installed in the intensive site

laboratory facilities when possible.

Telephone, fax service, and a satellite communication

system will be provided by the GTE Project Office at the operations center at

each intensive site. Cellular

phones may be provided to the Mission Scientists, Aircraft Managers, and Project

Representatives at some sites, depending upon the availability of normal public

telephone service. When cellular

phones are provided, they are to be used only for local, in-country calls, and

only when local telephone service is not available.

No long distance telephone calls are to be made on the cellular phones.

Use of the satellite system is described in Section

7.5.8.5.

All of the communication services provided by the GTE Project Office are

to be used only for conducting official business related to the TRACE-P mission.

7.5.10.2 Personal Communications

No personal communications or communications related to

non-GTE business are to made on the project-provided communications systems.

Personal phone calls will be reimbursed as follows:

|

Domestic |

|

|

Daily (must include overnight) |

Not to exceed average of 1 call/day |

|

|

Not to exceed $5/day |

|

|

|

|

Foreign |

|

|

Daily (must include 2 overnights) |

Not to exceed average of 1 call/day |

| Not to exceed $7/day |

Note that government calling card cannot be used for

personal calls, however for official business calls, the use of the government

card precludes the need for any record keeping.

7.5.10.3 Integration Sites and Transit Site Stops

No special communication systems or services will be

provided at the aircraft integration sites or the transit site stops.

Reimbursement for calls from these sites will be subject to the same

limitations as previously presented for the intensive sites.

Internet access will be established at Yokota Air Base through their Network Operations Center. The primary connection at Yokota will be dial-up with connection speeds up to 33.6Kbs (Note: standard RJ11 blocks/jacks are used). The project office has arranged to obtain limited access to T1 lines using RJ45 jacks to download large files. T1 access is limited to GTE Project Office use only.

Internet

access will be established at Hong Kong through a local Internet Service

Provider. The connection is anticipated to be dial-up with a connection speeds

up to 56Kbs. The telephones will have an analog data port to plug your modem

into. Do not plug modems directly into wall jacks, many of these are digital and

may destroy or damage your modem. An Ultra-line connection (access speeds up to

1.5Mbps using 10/100Mbs Ethernet card) will be available in Hong Kong also.

There will be no Internet access provided at Hawaii, Wake Island, Guam or Midway. Limited access may be available through the satellite communication system.

7.5.10.5 Satellite Communication

Systems

INMARSAT

B: A portable INMARSAT B

satellite-based communication system, coupled to the "remote-based"

PC, will provide the communication link for a high data rate (56/64 KBPS)

PC-to-PC transfer of the meteorology products (e.g. calculated and satellite

images) stored on the home based PC located at Florida State University (FSU).

The communication system will have the capability for

voice, low-speed Internet access, and direct PC-to-PC high-speed data transfer.

Because of the high cost of airtime, only the PC-to-PC communication will

be used, except for emergencies as determined by the GTE Project Office.

The GTE Project Meteorologist (see Figure

7.1-1) will be

the designated operator for the communication system. The GTE Project Meteorologist and satellite communication

system will travel with the NASA C-130 throughout the entire mission.

Table

7.5.10.5-1 gives the azimuth and elevation look angles

from the site antenna location to the Pacific Ocean Region [POR] (0 deg N, 178

deg E, 35870 km) or the Atlantic Ocean Region West [AOR-W] (0 deg N, 54 deg W,

35870 km) Inmarsat communication satellites.

|

Site |

Azimuth, deg |

Elevation, deg |

|

Wallops |

150.0 |

45.0 |

|

Dryden |

250.0 |

15.0 |

|

Hawaii |

240.0 |

55.0 |

|

Wake Island |

155.0 |

67.5 |

|

Guam |

125.0 |

57.0 |

|

Hong Kong |

110.0 |

25.0 |

|

Yokota, Japan |

135.0 |

37.5 |

|

Midway Island |

195.0 |

55.0 |

INMARSAT AERO: The DC-8 and P-3B aircraft will be equipped with satellite communication (SATCOM) systems allowing for voice communications between the two aircraft and with the ground. The existing SATCOM on the DC-8 is sufficient for these purposes. The P-3B will be equipped with an AERO Mini-M SATCOM system prior to the TRACE-P field mission. During TRACE-P coordinated research flights, the Mission Scientists will speak with each other via the SATCOM systems in order to focus the flights on areas of interest as determined by the onboard scientific instruments.

7.6 Intensive Site Support and Meetings

Principal Investigator requested support requirements are included in Appendix I and Table 7.6-1 and Table 7.6-2.

Table

7.6-1

Support Needs for DC-8 PIs

|

PI

Name |

Description |

|

Anderson |

50 sq. ft . work area; 2 tables; 3 chairs; 120VAC;

2 net connects; chem storage; small CO2 cylinder; 60 sq.ft. storage |

|

Apel |

1 table; 1 chair; 1 net connect |

|

Avery |

2 tables; 3 chairs; 115 VAC—8 receptacles; 2 net

connects; 1 phone; fax; storage space for 8 ft X 8 ft |

|

Barrick |

8 ft X 12 ft work area;

2 tables; 2 chairs; 115 VAC; 2 net connects; 1 phone; fax; 8 ft X

8 ft storage area |

|

Blake |

11 sq ft work area; 1 table ; 2 chairs; 30 amp

connection; e-mail; 1 phone; fax; transport for snakes from storage to

planes; boxes to store 150 cu ft |

|

Browell |

200 sq. ft. storage |

|

Brune |

400 sq. ft. work space; 2 tables; 4 chairs; fume

hood; ehhaust; 2kVA, 115V 60Hz; 2 net connects; 1 phone; fax; chem

storage; rack for GN2 cylinders; laser curtains; 100 sq. ft. storage |

|

Fried |

1 table; 1 chair; 6-foot workbench; 60hz, 115VAC; 1

air cyl; access to LS-160 for daily dewar filling; storage for 2 support

boxes containing pumps, etc; 1 phone |

|

Heikes |

8 ft wet lab bench; desk; 2 chairs; fume hood; 115

VAC, 20 amps; 2 net connects; phone; fax; chem storage; water; refrig/freezer;

pure air |

|

Sachse |

2 tables; 4 chairs; 60 hz power; 2 net connects;

phone; fax; chem storage; 75 sq. ft. storage |

|

Sandholm |

3 tables; 5 chairs; 400 hz & 60 hz power; 1 net

connect; phone; chem storage; water; 55 sq. ft. storage |

|

Shetter |

30 sq. ft. work space; 1 table; 2 chairs; 115V; 1

net connect; phone; 50 cu. Ft. storage |

| Singh | 200 sq. ft. work space; 1 table; 2 chairs; AC 60 Hz, 20 amps; 1 net connect; phone; fax; chem storage; water; refrig/freezer; gas cyl; LN2, CO2 ice, H2O ice; 80 sq.ft storage |

|

|

|

Meetings during field deployment of TRACE-P will be

conducted to: ensure proper

exchange of information on schedules, provide updates for local logistical

requirements, report aircraft and instrumentation status, review meteorological

conditions, discuss science objectives relative to measurements results, and

plan mission flight scenarios.

Typically, at each deployment site a general status and flight-planning meeting will be convened during the afternoon of each non-flight day. On flight days, a pre-flight status meeting will be convened approximately one hour prior to aircraft door closing on the P-3B and DC-8. A post flight debriefing will be conducted immediately after each flight. The pre-flight and/or post flight briefings may be conducted aboard, or near, the aircraft. Upon arrival of each aircraft at a new deployment site, the GTE Project Manager (Figure 7.1-1), or his designee, will conduct an initial "orientation" briefing. All field deployment personnel are welcomed to all meetings, but as least one spokesperson from each PI team is required at the general status/flight-planning meeting and at the pre- and post-flight debriefings. No formal meetings will be convened on mission down days.

An important function of the general

status/flight-planning meeting is the development of the flight plans for the

next local or transit flight in accordance with the Expedition objectives

addressed in Section 2.0 of this document. Final plans for a flight are required

at least twelve hours prior to take off time.

The final flight plans will, however, be strongly influenced by

meteorological conditions. To facilitate the development and selection of the

flight plans, typically, two preliminary flight-planning meetings will be

conducted prior to the general status/flight-planning meeting. The first will

involve the on-site mission scientists and mission meteorologists. The purpose

of this meeting will be to review and select the leading options for the

upcoming flight, as well as to consider back-up flight options, if appropriate. The second preliminary flight planning meeting will involve

mission scientists, mission meteorologists, aircraft navigators, aircraft

mission managers, pilots, and the GTE Project Manager or his designee. The

purpose of this meeting will be to discuss the reccommendation(s) by the mission

scientists for a flight plan, and to develop the draft flight plan that will be

reviewed by the Science Team during the

general status/flight-planning

meeting. Prior

to these preliminary flight-planning meetings, the mission scientist will

solicit inputs from the PIs relative to potential flight scenarios, and PIs may

participate in any of these preliminary meetings. It is anticipated that the

recommended flight plan emerging from

the preliminary planning will represent the best option for the upcoming flight

based on the science objectives and most probable meteorological conditions, and

only minor alterations to the flight plan by the Science Team will be required.

Usually, an alternate flight

plan will be developed

incorporating different meteorological conditions, if such an occurrence is

significantly probable.

The general status/flight-planning meetings will

also serve as a forum for the Science Team to briefly review results from

previous flights. Several special science discussion team meetings will also be

scheduled by the Mission Scientist for more focused and in depth reviews of

mission results relative to the mission objectives.

The schedule for these will depend upon the progress of the field

operations. All meetings will involve both P-3B and DC-8.

During the pre-flight status meeting convened before each

flight, the flight crew and science team will review the latest weather

information, flight plans, instrument status, and make a Go/No-Go decision with

respect to the prime and alternate flight plans. The Mission Meteorologist(s),

Mission Scientists, Aircraft Manager(s), Project Manager or his designee, pilot,

and at least one representative from each investigator team are expected to

participate.

The post-flight debriefing will be held to review all

aspects of the mission from weather conditions to instrument performance, to

determine PI aircraft access requirements, and to determine aircraft and

instrument readiness for the next scheduled missions. The Aircraft Managers,

Mission Scientists and Meteorologists, Project Manager or his designee, Chief

Pilot, and at least one representative from each investigator team are expected

to participate.

Press briefings may be scheduled as a result of request

from local media. The GTE Project

Office will have prepared Press Release Kits for distribution at such briefings.

The GTE Project Manager will serve as the main point of contact for the press

briefings, however the Mission Scientist will serve as the primary spokesperson

for the Science Team at these briefings. PIs may also be asked to make

presentations and/or be available to answer questions or to elaborate on

scientific issues. Aircraft tours may also be provided with the approval of the

cognizant Aircraft Manager.

7.7 Aircraft Access on Parking Ramp

With the exception of planned down-days, the aircraft will normally be open and power available from 0800 to 1700 local time. At all of the deployment locations, although the aircraft may be open, access will be tightly controlled. Access to the aircraft by walking will not be permitted at any location; therefore transportation will have to be arranged to and from the aircraft. A bus schedule will be posted at the meeting room entrance (or hotel front desk), and any deviations from that schedule will have to be arranged through the Site Manager or his designee. On flight days, the aircraft will nominally be accessible about four hours before take-off and will be secured approximately two hours after landing. Access to the aircraft outside of these times must be coordinated with the GTE Project Manager, or his designee, and with approval of the DC-8 or P-3B Aircraft Manager

Only designated aircraft crewmembers will open the

aircraft and operate the power distribution panel controls.

Experimental apparatus under power will not be left unattended.

Under no circumstances will the aircraft be left open and unattended.